What is a PAT Test?

Although they’re non-compulsory by law, PAT tests have become a standard practice for businesses wishing to comply with legislation regarding electrical safety. From landlords to construction sites, PAT testing is a concern for any business or individual using electrical equipment in their operations. They are the most effective way to avoid the liabilities that can arise from unsafe electronics in a workplace or property.

A PAT test is a multi-stage assessment of some types of electrical appliances and equipment to ensure their electrical safety. A full PAT test involves three stages; the first stage includes informal checks from the users, while stages two and three are formal visual and physical tests. The extent of testing that an appliance requires will depend on its electrical class and potential risk level. Considering the nature of the job, only a qualified electrician or competent employee should carry out PAT testing.

What is a PAT Test?

A PAT test is a routine inspection and assessment of some types of electrical appliances to ensure they’re safe to use. The purpose of a PAT test is to identify potential electrical safety defects in the appliance, thus preventing electrical accidents.

What Does PAT Stand For?

The acronym ‘PAT’ stands for ‘Portable Appliance Testing’. However, this name is somewhat misleading, as PAT tests are a requirement for several categories of electrical appliances.

The current legislation regarding PAT tests does not outline a specific definition of what a ‘portable appliance’ is; the general interpretation of this term is any appliance that has an attached plug and plugs into a wall socket. PAT tests are therefore necessary for a range of electrical appliances, both fixed and portable.

Which Appliances Need a PAT Test?

There are 7 categories of electrical appliances that need routine PAT testing to ensure their safety. These include:

- Stationary appliances: appliances that typically remain in one position, e.g. fridges, washing machines, or vending machines.

- Fixed appliances: appliances fixed in a permanent location or fastened permanently to a support, e.g. storage heaters, cookers, or hand dryers.

- Portable appliances: appliances that are moved during usage while connected to a power supply, e.g. vacuum cleaners.

- Moveable appliances: appliances under 18kg that sit in one place but could be moved easily, e.g. toasters, kettles, microwaves, or electric fans.

- IT appliances: IT equipment, e.g. computers, monitors, laptops, printers, or photocopiers.

- Handheld appliances: appliances that are held in the hand during usage, e.g. hairdryers, other heated hair styling tools, or powered tools like electric drills.

- Electrical cables and chargers: any electrical cable or charger, e.g. extension cables, IEC lead, or cable reels.

What Are the Different Classes of Appliances in PAT Testing?

The appliances subject to PAT testing fall into one of three categories based on their electrical class; they are either Class 1, Class 2, or Class 3, with Class 1 being the highest risk appliances. Electrical appliances sold in the UK come with symbols that indicate which class they belong to.

Class 1 Appliances

Appliances in the Class 1 category are those with the highest risk of potential danger. They typically only have basic insulation, instead relying on the earth for further protection.

Class 1 appliances require a full PAT test, including both a visual and physical inspection, to ensure their electrical safety.

Class 1 appliances include:

- Kettles, toasters, and microwaves

- Dishwashers

- Washing machines and tumble dryers

- Fridges and freezers

- Chargers for phones, tablets, and laptops

- Desktop computers

- Vending machines

- Industrial machinery

Class 2 Appliances

Appliances in the Class 2 category have less risk associated with their electrical safety. These appliances do not rely on the earth for safety, and have more insulation than the previous class. Class 2 appliances typically don’t require full PAT testing and will suffice with a visual inspection alone.

Class 2 appliances include:

- Lamps

- Televisions

- Blenders and food mixers

- Heated hair styling tools like hair dryers and straighteners

- Radios and CD players

- DVD players

- Lawnmowers

Class 3 Appliances

Appliances in the class 3 category are the lowest voltage and therefore carry the lowest risk of danger. These appliances themselves won’t require full in-depth PAT testing, although it will likely be necessary to test their wires, cables, or chargers.

Class 3 appliances include:

- Mobile phones

- Laptops and tablets

- Cameras

- Torches

For Which Businesses Are PAT Tests Recommended?

It’s recommended that all businesses or operations that use electrical equipment should carry out routine PAT testing. Therefore, PAT testing is a recommended practice for offices, hotels, restaurants, landlords, healthcare facilities, and construction and manufacturing operations. Those who are self-employed should also conduct PAT tests on their equipment, even if they work from home.

Are PAT Tests Compulsory By Law?

PAT tests are not a legal obligation and are therefore not compulsory by law to carry out. Still, PAT testing has become a standard practice to meet other legal requirements outlined in current UK legislations.

An example of these legislations includes the Electricity at Work Regulations 1989; this legislation states that any electrical appliance with the potential to cause injury must be maintained in safe condition. Another example are the government guidelines for landlords, who must ensure that ‘all electrical appliances they supply are safe’.

While these legislations exist, they don’t specify what must be done, how frequently it should be done, and who should carry it out. I.e, there are no legal obligations within the legislations for the routine inspection or testing of electrical appliances. Despite this, PAT tests are best practice for businesses and landlords to comply with the legal requirements for electrical safety in their properties.

Why Are PAT Tests Necessary?

As we’ve explained, there are two main reasons why PAT tests are necessary, despite not being a legal requirement. Primarily, PAT tests are used to ensure the safety of electrical appliances to their users. They are also the easiest way for businesses to meet the legislations that do exist regarding the general safety of electrical appliances.

Current legislations in the UK state that businesses and landlords must maintain their electrical equipment in safe working condition. To comply with these legislations, PAT testing has become the standard practice for those seeking to meet their legal safety requirements; PAT tests are the most effective way to negate the risks of electrical accidents, especially for larger or higher-risk operations.

So, although it isn’t compulsory to conduct PAT tests specifically, they’re the easiest way for a business to avoid any breaches of legislation. Depending on the situation, there are serious consequences if a business fails to meet their legal requirements for electrical safety; the penalty can be up to 2 years imprisonment and an unlimited fine for those liable in the worst cases. Routinely PAT testing electrical equipment will help a business to avoid these potential penalties.

Do I Need to Keep a Record of My PAT Tests?

Again, there are no legal requirements to conduct or keep records of PAT tests on electrical appliances. It also isn’t necessary to label the equipment that has been tested. However, this is another practice that is best to keep up with for the benefit of the business.

Keeping a full record of testing, and labelling the equipment appropriately, is best to monitor and review the maintenance scheme. Having a written record of the PAT tests will allow the business or landlord to demonstrate their maintenance activities; it acts as proof of the business’ compliance with legislation to regulators, insurers, and customers. This will therefore help to protect the business from legal liabilities in the future.

Who Can Conduct PAT Tests?

Electrical jobs like PAT tests must be carried out by those with the necessary certifications, skills, and experience with the work. In other words, only registered electricians should carry out PAT testing to avoid any dangerous situations.

With that said, businesses can carry out their own PAT tests; this is on the condition that the individual doing the testing is completely ‘competent’ in the area. To be classed as competent in PAT testing, the person conducting the test must meet these standards:

- They have a sufficient knowledge of electricity

- They have extensive experience with electrical work

- They know how to properly visually inspect electrical equipment

- They’re able to carry out a PAT test competently

- They have a thorough understanding of the potential hazards involved in PAT testing

- They know what precautions to take to prevent harm from the potential hazards of PAT testing

- They’re able to decide whether it’s safe to continue with PAT testing

- They can understand and interpret the results of the PAT tests

If a business would prefer to do its own PAT testing, there are training courses available for the relevant individuals. The business would also need to purchase their own PAT testing equipment.

What Does a PAT Test Involve?

According to guidance from the Health & Safety Executive (HSE), full PAT testing should involve three stages. The first stage involves informal user checks; the latter stages include a formal visual inspection and physical test with specialised PAT testing equipment.

Stage 1: User Checks

Anyone who uses the electrical appliance in question should receive, at minimum, basic training on how to safely use it. All users should be aware of the potential hazards of the equipment and how to visually check it for damage. Businesses should provide this training as part of employee inductions and/or whenever they purchase new equipment.

Stage 2: Visual Inspection

The formal PAT test will initially involve a visual inspection of the electrical appliance. The HSE states that the visual inspection can identify about 90% of problems, with many appliances only needing a visual inspection alone. This inspection can be carried out by a professional electrician or competent member of staff.

Before undertaking the inspection, the inspector must first turn off and unplug the appliance. They should then inspect the appliance following this checklist:

- Check the plug – Check the appliance’s plug for signs of damage, e.g. cracks, bent pins, or burns. Ensure that the wiring is intact; the live, neutral, and earth conductors should be securely connected to their correct terminals.

- Check the cables – Check the appliance’s cable for signs of damage, e.g. cuts, abrasions, or fraying. The appliance automatically fails if the cable has any exposed wiring.

- Check the appliance itself – Look over the actual appliance for obvious signs of damage, e.g. cracks, burns, corrosion, or other physical damage to the casing.

- Check the mains socket connecting the appliance – Check the connecting mains socket for cracks, loose fittings, and signs of overheating. Although this isn’t part of the physical PAT test, the socket still requires assessment during the visual inspection.

- Check the RCD (Residual Current Device) – Inspect the RCD for signs of damage and check that the operating current is correct. Use the ‘test’ button to ensure the RCD is in working order.

- Check the environment – Look over the surrounding environment for hazards, e.g. trip hazards from cables, fire and water hazards, or overloaded extension leads.

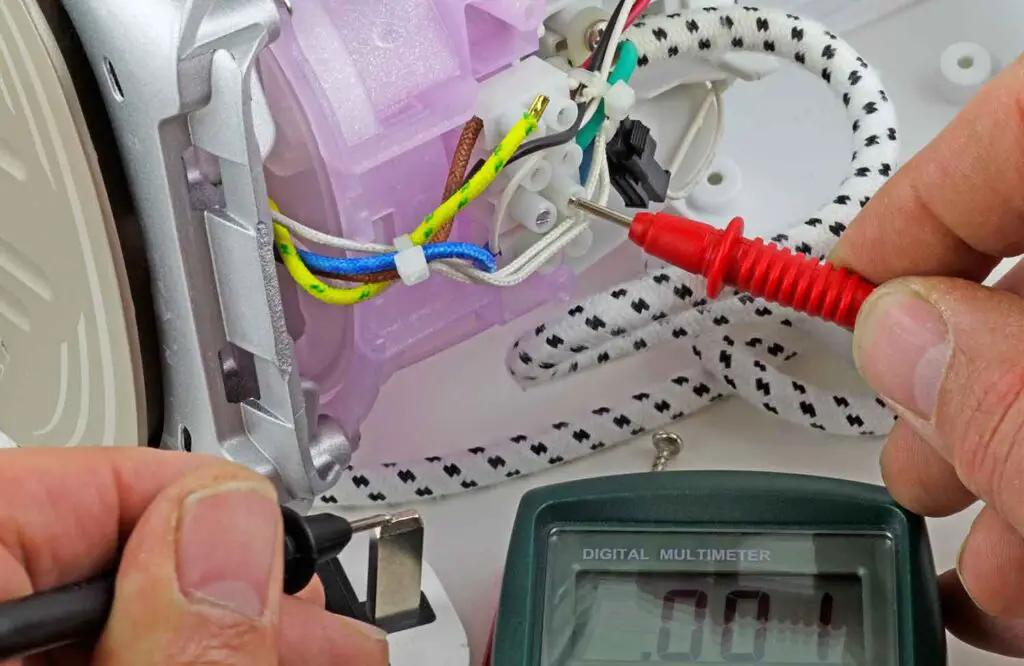

Stage 3: Physical Inspection with PAT Testing Equipment

The final stage is to carry out a physical inspection of the appliance with specialised PAT testing equipment. Again, this stage should only be conducted by someone with sufficient training and experience in PAT testing.

The inspector will use a PAT tester device to physically assess the appliance in question. This device tests several aspects of the appliance, including earth continuity, lead polarity, and insulation resistance. The testing device will also indicate whether the appliance passed or failed the PAT test overall.

After their inspection, the inspector should place a pass or fail sticker on the appliance and make a record of the results. The business should then receive a report detailing the inspection results. All appliances that fail the PAT test must be removed immediately for repair or replacement; if repaired, the appliance must then pass another PAT test before it can be declared safe for use.

What Does a PAT Test Report Contain?

Once the PAT test is completed by the qualified individual, the business should receive a PAT test report.

At minimum, this report will contain the following details:

- An inventory of each electrical appliance, including details on their name, type, location, and a description.

- Full test results from the PAT tests of each electrical appliance.

- A list of every appliance that failed the PAT test with reasoning for the failures.

- A pass or fail label placed visibly on each appliance that details the date of inspection, date of next test, and the tester’s signature.

The person who carried out the PAT test and report will be able to talk it through with the business upon request. They will explain the results and advise on any further action that may be required.